Exploring the Circular Guide Rail Circulation Line

Share

Table of Contents

- Exploring the Circular Guide Rail Circulation Line

- Exploring the Circular Guide Rail Circulation Line

- The working principle of the circular guide rail line

- Advantages of circular guide rail circulation lines

- Application fields of circular guide rail circulation lines

- Technical parameters of circular guide rail circulation line

- Installation and debugging of circular guide rail circulation line

- Maintenance and maintenance of circular guide rail circulation line

- The development trend of circular guide rail circulation lines

- Key points for selecting circular guide rail circulation lines

- Market status and prospects of circular guide rail circulation lines

Exploring the Circular Guide Rail Circulation Line

Exploring the Circular Guide Rail Circulation Line

The circular guide rail circulation line is a piece of equipment that plays an important role in modern industrial production. It can achieve efficient, precise and continuous material transportation, providing strong support for the optimization and automation of production processes.

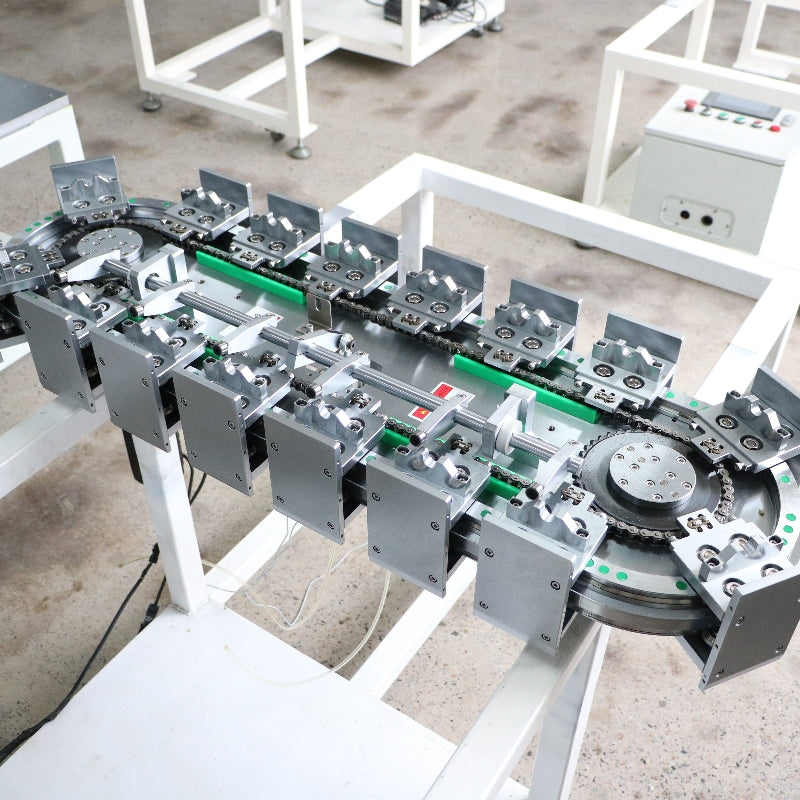

Its components are rich and diverse. Among them, the linear guide rail provides stable guidance and support for the linear motion of the object; the arc guide rail allows the object to run smoothly on the curved track and realizes flexible changes in the path; the rotating wheel plays a role in the entire system. The key role of the transmission is to drive the movement of the load-bearing chain links and other components through its own rotation; the load-bearing chain links are responsible for carrying and transporting objects, ensuring that materials move stably on the circular track.

These components fit together and work together. The perfect combination of linear guide rails and arc guide rails creates a complete circular track, allowing objects to circulate along a preset route. The rotating wheel is connected to the driving device and transmits power to the load-bearing chain link, thereby pushing the object forward along the track. While bearing the weight of objects, the load-bearing links work closely with other components to ensure the smooth operation of the entire cycle line.

In practical applications, the performance and quality of each component directly affects the overall effect of the annular guide rail loop. For example, high-precision linear guides and arc guides can ensure the accuracy and stability of object movement; high-quality rotating wheels and load-bearing links can improve the load-bearing capacity and service life of the system. The close cooperation and coordinated operation between them are an important guarantee for the efficient work of the curved guide rail circulation line.

The working principle of the circular guide rail line

The circular guide rail circulation line can achieve efficient and precise circulation motion, thanks to the coordinated work of its carefully designed transmission system and control system.

The transmission system plays a key role in the operation of the curved rail loop line. Usually, it includes workstation device, transmission device and carrying device. The station device is responsible for determining the specific position and operating links of the object on the circulation line; transmission devices, such as motors, reducers, transmission chains, etc., provide stable and continuous power for the entire system to ensure that objects can move smoothly along the predetermined track; The load-bearing device bears the weight of the object and has various forms, such as conveyor belts, chains, raceways, etc., which can be selected according to different material characteristics and transportation needs. During the transmission process, various components work closely together and undergo careful engineering design and deduction to avoid conflicts between components, thereby ensuring accurate operation in various environments.

The control system is also indispensable for the precise operation of the circular guide rail loop. It is mainly used to ensure that the workstations within the line body meet accuracy requirements and that the auxiliary equipment operates cyclically within the specified working hours. Through precise control, each workstation can accurately perform predetermined operations and achieve an efficient production process. For example, during the initial positioning, the control system uses the servo drive to pulse the motor to drive the workstation to the vicinity of the positioning pin to achieve preliminary position determination. During secondary positioning, the gap in the belt drive and the action of the side cylinder and solenoid valve are used to extend the positioning cylinder and rotate the positioning pin to recalibrate the work station, thereby achieving high-precision repeated positioning.

The cooperative work of the transmission system and the control system is the core of the circular guide rail circulation line to achieve stable circulation motion. The transmission system provides power and motion paths, while the control system accurately adjusts and positions the motion. The two cooperate with each other so that the annular guide rail cycle line can complete materials or materials with high speed, high precision and high stability in different working scenarios. The cyclic transportation of workpieces brings great convenience and efficiency improvement to modern industrial production.

Advantages of circular guide rail circulation lines

The circular guide rail circulation line has shown many significant advantages in modern industrial production. Compared with traditional conveyor lines, its performance is particularly outstanding in key aspects such as load capacity, accuracy and speed.

In terms of carrying capacity, the curved guide rail circulation line has strong carrying capacity. Its unique structural design and high-quality material selection enable it to withstand heavier loads and meet various mass production needs. In contrast, traditional conveyor lines may suffer from problems such as insufficient stability and stuck operation when carrying heavier items. The high load-carrying capacity of the circular guide rail circulation line provides a reliable solution for enterprises to handle large-weight and large-volume material transportation, greatly improving production efficiency. Precision is another great advantage of curved rail loops. The precision-processed guide rails and advanced positioning system ensure the high-precision positioning and accuracy of the movement trajectory of objects during transportation. This high precision can effectively reduce errors and improve product quality and consistency. Due to its structural and technical limitations, traditional conveyor lines are often difficult to achieve the level of annular guide rail circulation lines in terms of precision control, which can easily lead to deviations in the product during the production process and affect the final quality.

In terms of speed, the circular rail loop line also performs well. Its efficient transmission system and optimized operating mechanism enable objects to circulate on the track at a fast speed. This not only speeds up the production cycle, but also completes more production tasks per unit time. In comparison, traditional conveyor lines usually operate at a slower speed and cannot meet the needs of modern and efficient production.

In addition, the curved guide rail circulation line also has the advantages of high stability, low maintenance cost, and strong adaptability. Its stable operating performance reduces failures and downtime in production, thereby reducing production costs. At the same time, relatively simple maintenance work and low maintenance costs save enterprises a lot of human and material resources. Moreover, it can adapt to different working environments and production requirements, and has a wider range of application scenarios.

Application fields of circular guide rail circulation lines

Circular guide rail circulation lines have extensive and important applications in electronics, electrical, automation and other industries.

In the electronics industry, annular guide rail circulation lines provide strong support for the automated production of electronic products. For example, during the assembly process of smartphones, the circular guide rail circulation line can accurately transport various components to the corresponding work stations, achieving efficient assembly of screens, batteries, motherboards and other components. Through precise positioning and fast transportation, production efficiency and product quality are greatly improved. At the same time, in the production line of electronic components, the circular guide rail circulation line can realize the seamless connection of a series of processes such as loading, assembly, welding, hot stamping, CCD detection and unloading, ensuring the continuity and stability of the production process.

In the electrical industry, ring rail loops play a key role in the manufacturing of electrical equipment. For the assembly of large electrical equipment such as transformers and switch cabinets, the circular guide rail circulation line can carry heavier components and accurately transport and assemble them according to a predetermined process. Its high load-bearing capacity and stable operating performance effectively ensure the production quality and efficiency of electrical equipment.

In the automation industry, the circular guide rail circulation line is an indispensable part. In automated production lines, there are basically multiple processes, which require high precision, fast speed, and fast start and stop times for different processes. The curved guide rail circulation line can meet these stringent requirements. One slide is arranged for one process, and the slide can move quickly on the circular guide rail to ensure that the product loading, assembly, and final unloading processes are completed quickly and accurately. For example, in the automobile parts production line, the circular guide rail circulation line can realize the cyclic automated assembly and inspection of parts, improving the automation and consistency of production. In addition, in the field of new energy, the circular guide rail circulation line also has excellent performance in the production of lithium batteries. It can accurately transport battery components and ensure efficient connection between various processes, thereby improving battery production efficiency and quality. In the field of logistics and transportation, the curved guide rail circulation line can realize the rapid sorting and transportation of goods, improving the efficiency and accuracy of logistics and distribution. Technical parameters of circular guide rail circulation line

Technical parameters of circular guide rail circulation line

The circular guide rail circulation line has a series of key technical parameters, which play a vital role in its performance.

The first is the track diameter. The size of the track diameter directly affects the layout and application scenarios of the annular guide rail loop line. Smaller track diameters are suitable for sites with limited space and enable compact layouts, but may limit load-carrying capacity and operating speed to a certain extent. The larger track diameter can provide higher load-bearing capacity and faster operating speed, and is suitable for large-scale, high-speed operation production environments.

Carrying capacity is another key parameter. It determines the weight and quantity of items that the circular rail loop can transport. High load-bearing capacity means that heavier and larger cargo or parts can be handled, thus meeting the needs of heavy industrial production. The load-bearing capacity is affected by the guide rail material, structural design, and the performance of rollers and other components. If the carrying capacity is insufficient, the system may run unstable or even malfunction.

Running speed is also a technical parameter that cannot be ignored. Faster running speed can improve production efficiency and shorten production cycle. However, operating at too high a speed may have a negative impact on system stability, accuracy, and noise levels. In addition, the operating speed is also restricted by factors such as the performance of the drive system, the smoothness of the track, and the load conditions.

These technical parameters are interrelated and influence each other. For example, larger track diameters often support higher load-bearing capacity and faster operating speeds, but also increase the cost and space requirements of the equipment. In practical applications, these technical parameters need to be comprehensively considered according to specific production needs and working environment to select the most appropriate circular guide rail circulation line to achieve efficient and stable production operations.

Installation and debugging of circular guide rail circulation line

The installation and debugging of the circular guide rail circulation line is a key link to ensure its normal operation and efficient work. The installation steps, debugging methods, possible problems and solutions will be explained in detail below.

Installation steps: First of all, after receiving the ring guide rail circulating line equipment, each component should be carefully inspected to ensure that there is no damage or missing. Then, install the motor, which is usually a critical step in the installation process. When installing the motor, make sure it is positioned accurately, firmly fixed, and well connected to other components. Next, place the entire device on the workbench for preliminary position adjustment and fixation.

Debugging method: Before debugging, be sure to run the car manually with the power off to check whether there is any interference. This step can detect potential mechanical collision problems in advance and ensure the safety of subsequent debugging. After confirming that everything is correct, then connect the circuit to ensure that the power line and control line are wired correctly. After completing the circuit connection, you can start power-on debugging. First, set the origin. After the origin is set, start running at low speed for testing. It is recommended that the initial speed be set at about 50% of the normal production operating speed. During low-speed operation, observe the smoothness of the line body and confirm that there are no abnormalities, then gradually increase the operating speed until it reaches the working speed. In addition, when designing and deploying control circuits, emergency stop switches and power switches must be set up to deal with emergencies. For fast running speeds, it is recommended to set acceleration and deceleration when starting and stopping to ensure that the car can run smoothly under load and reduce the impact of high speed and high inertia on the life of the equipment.

Possible problems and solutions: During the installation and debugging process, you may encounter some problems. For example, if the load-bearing slide is shaking on the track, this may be caused by loose rollers, and the manufacturer needs to be consulted for adjustment or replacement. If there is an abnormal sound, it may be that the track is loose or foreign matter has entered, or the reducer or coupling is damaged, which requires timely inspection and repair. In addition, if the equipment suddenly stops or malfunctions during operation, first check whether the power supply and circuit are normal, then check whether the connections of various components are loose, and take corresponding solutions according to the specific situation.

Maintenance and maintenance of circular guide rail circulation line

As an important piece of equipment in industrial production, the circular guide rail circulation line cannot operate stably without scientific and reasonable maintenance. The main points of daily maintenance include cleaning, lubrication and dust prevention.

Regular cleaning is the basis of maintenance. It is necessary to use appropriate tools and cleaning agents to carefully clean the tracks, rollers, load-bearing chain links and other parts of the annular guide rail to remove oil, dust and debris on the surface to prevent accumulation of dirt from affecting operating accuracy and smoothness.

Lubrication is essential for the proper operation of ring guides. The appropriate lubricant should be selected based on the frequency of use of the equipment and the working environment, and should be added or replaced according to the specified intervals. Good lubrication can reduce wear between components and extend the service life of equipment.

Dust protection is also a key part of maintenance work. When dust or other foreign matter enters the transmission system, it may cause abnormal wear and even damage components. Therefore, it is necessary to choose appropriate sealing devices or dust-proof devices, and at the same time keep the equipment operating environment clean.

In terms of maintenance cycles, generally speaking, it is recommended to conduct comprehensive maintenance at certain intervals. The specific cycle can be determined based on factors such as the frequency of use of the equipment and the harshness of the working environment. For circular guide rail circulation lines operating under high loads and harsh environments, the maintenance cycle should be appropriately shortened; under ideal working conditions, the maintenance interval can be appropriately extended.

Troubleshooting and handling of common faults is also an important part of maintenance work. For example, if there is abnormal noise when the equipment is running, it may be caused by loose tracks, worn parts, or foreign objects entering. At this time, it is necessary to stop the machine for inspection in time to find out the problem and carry out corresponding repairs or parts replacement. If the equipment runs poorly or freezes, it may be due to insufficient lubrication, component damage, or transmission system failure. The lubrication situation, the status of related components, and the transmission system need to be carefully checked and processed.

The development trend of circular guide rail circulation lines

As an important part of the industrial automation field, the circular guide rail circulation line is showing an eye-catching development trend. In the future, technological innovation will become a key force driving its continuous advancement.

On the one hand, with the continuous advancement of material science and manufacturing technology, the material and structure of the curved guide rail circulation line are expected to achieve major breakthroughs. New high-strength, wear-resistant and lightweight materials will be widely used to further improve the load-bearing capacity and operating speed of guide rails while reducing energy consumption. In terms of structural design, more compact and efficient layout will become the mainstream to adapt to the increasingly complex production environment and diversified production needs.

The integration of intelligent technology will also bring profound changes to the circular guide rail circulation line. By introducing advanced sensors and data analysis systems, real-time monitoring and predictive maintenance are achieved. This can not only effectively reduce equipment downtime and improve production efficiency, but also optimize operating parameters based on actual operating data to achieve more precise control and higher performance.

On the other hand, changes in market demand will also lead the development direction of curved guide rail circulation lines. As the global manufacturing industry transforms into high-end, intelligent and green, the demand for high-precision, high-speed and high-stability conveying equipment will continue to grow. Especially in emerging industries such as electronics, medical care, and new energy, the demand for circular guide rail circulation lines will show explosive growth.

At the same time, the market demand for customized solutions is also increasing. Different industries and enterprises have unique production processes and spatial layouts, so the circular guide rail circulation line needs to be personalized according to specific needs to achieve seamless connection and efficient collaboration with the existing production system.

Key points for selecting circular guide rail circulation lines

When selecting an annular rail loop, several key factors need to be considered to ensure it meets your specific production needs.

The work environment is one of the first considerations. If there is a lot of dust, debris or corrosive substances in the working environment, you need to choose a guide rail material with good protective performance and corrosion resistance. For example, in harsh environments, stainless steel guide rails may be more suitable because of their strong resistance to corrosion. In addition, ambient temperature will also affect selection. If it is in a high or low temperature environment, guide rails and related components that can adapt to the corresponding temperature range should be selected to ensure the normal operation of the equipment.

Load requirements are another important aspect. It is necessary to clarify the weight, volume and quantity of items that the circular guide rail circulation line needs to carry. High load demands may require components such as stronger rail structures and rollers with greater load-bearing capacity. At the same time, it is also necessary to consider whether there are special load conditions such as punching force. If so, it is necessary to increase the load capacity margin accordingly during model selection to ensure the stability and safety of system operation.

Precision requirements have a vital impact on product quality and production efficiency. For production links with high precision requirements, such as precision assembly in the electronics industry, it is necessary to choose annular guide rail circulation lines with high-precision positioning capabilities. This includes the accuracy of initial positioning and repeated positioning. Generally, the positioning accuracy can reach ±0.01 mm, and after adjustment, the repeated positioning accuracy can reach ±0.05 mm. In addition, the manufacturing process and materials of the guide rail should also be considered to ensure accuracy and stability in long-term use.

In addition, it is also necessary to consider the number of workstations, the center distance between adjacent workstations, the time required from one workstation to the next, the size of the carrier plate, the connection method between the slides, the overall machine size requirements and Shape, installation method, line rotation direction and other factors. In short, when selecting an annular guide rail circulation line, various factors must be comprehensively and carefully analyzed to ensure the rationality and applicability of the selection and provide a strong guarantee for efficient and stable production operation.

Market status and prospects of circular guide rail circulation lines

Currently, the market for circular guide rail circulation lines is booming. From the perspective of market size, with the transformation and upgrading of the manufacturing industry and the growing demand for automation, its market size continues to expand. According to relevant data, in recent years, the global market size of curved guide rail circulation lines has increased year by year, especially driven by the application needs of electronics, electrical, automation and other industries, the growth trend is obvious.

In terms of competition situation, there are many market participants and competition is fierce. The market prospect of circular guide rail circulation lines is broad. With the rise of emerging industries, such as new energy vehicles, smart manufacturing, 5G communications, etc., the demand for high-precision, high-speed, and high-stability conveying equipment will further increase, providing more application scenarios and applications for annular guide rail circulation lines. development opportunities. At the same time, technological innovation will become a key factor driving market development. For example, the integration of intelligent technology will enable the circular guide rail circulation line to have stronger self-diagnosis and adaptive capabilities, further improving production efficiency and product quality.

In addition, the deepening of the concept of environmental protection will also promote the development of circular guide rail circulation lines in a green and energy-saving direction. In the process of R&D and production, enterprises will pay more attention to the environmental protection of materials and efficient use of energy to meet the market's requirements for sustainable development. In terms of market structure, with industry integration and survival of the fittest, market concentration is expected to further increase, and companies with core competitiveness will gain greater market share.