What types of guide rails are there?

Share

Table of Contents

What types of guide rails are there?

1. Sliding guide rail

Sliding guide rails are one of the most traditional forms of guide rails, which achieve linear motion of components through sliding friction. This kind of guide rail usually consists of a closely matched guide rail and a slide block (or slide seat), and the surface needs to be lubricated to reduce wear. The sliding guide rail is simple and durable, but has a large friction coefficient and relatively high movement resistance.

2. Rolling guide (linear guide)

Rolling guides use rolling elements such as balls or rollers to reduce friction and provide smooth linear motion. This type of guide rails includes two categories: square guide rails (linear guide rails) and circular guide rails. They are characterized by low friction coefficient and high movement accuracy, but compared with sliding guide rails, the manufacturing cost and maintenance cost are higher.

a. Square guide rail (linear guide rail)

Square guide rails have high rigidity, high load capacity and high precision, and are widely used in various high-precision and heavy-load situations, such as CNC machine tools, industrial robots, etc.

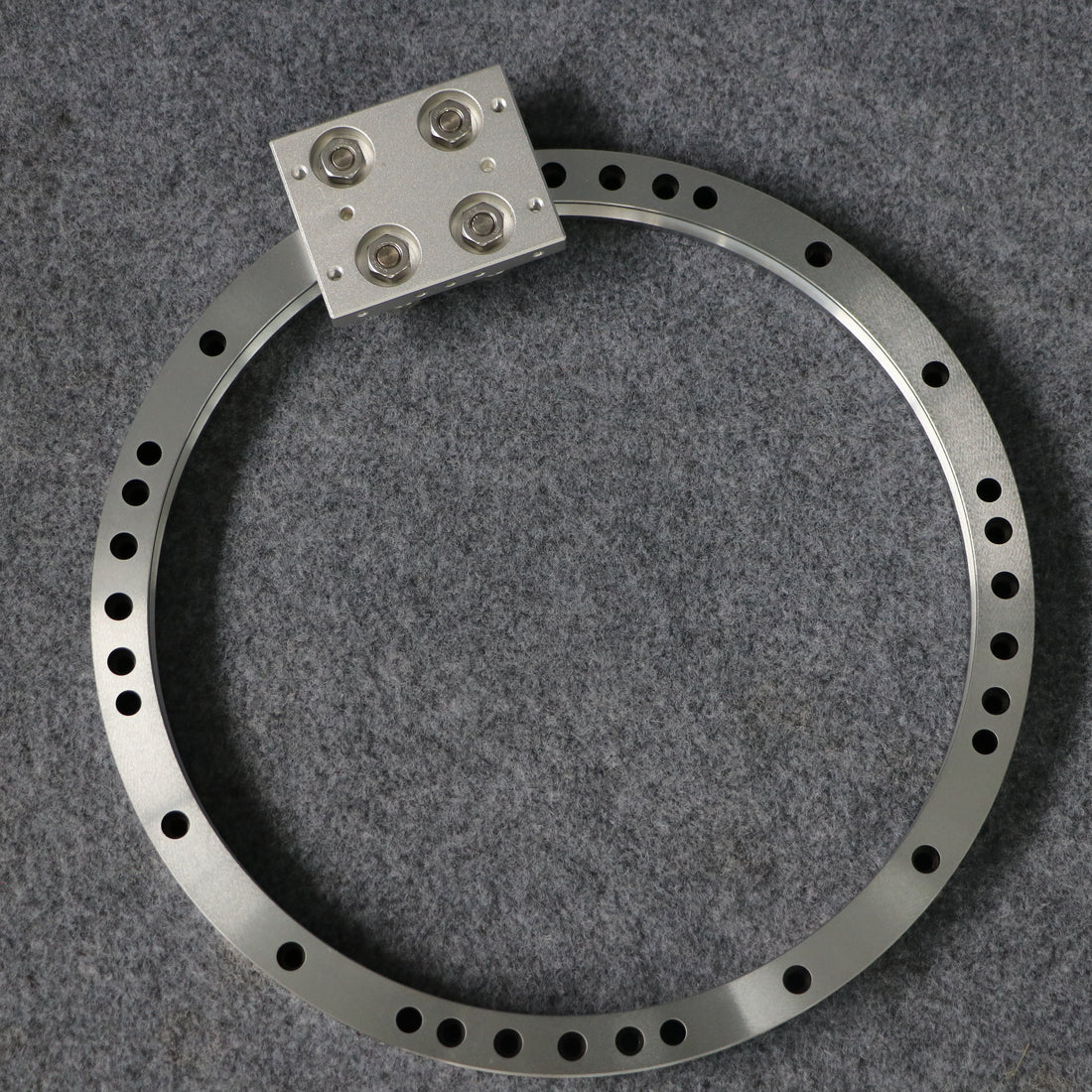

b. Circular guide rail

Circular guide rail refers to a guide rail with a circular cross-section. It is simple and low-cost, and is suitable for some occasions where the accuracy requirements are not particularly high.

3. V-shaped guide rail

The V-shaped guide rail has a V-shaped cross-section and is usually used with a matching V-shaped slider or roller. This kind of guide rail can automatically adjust the center, provide stable guidance and good anti-eccentric load ability, and is suitable for applications that require self-aligning ability.

4.Flexible guide rail

Flexible guide rail is a new type of guide rail made of flexible materials (such as plastic) that can be bent to a certain extent. They are mainly used for motion control of some light loads and non-standard paths, such as the guidance systems of some automation equipment and light robots.

To summarize

Each type of guide rail has its specific application areas and advantages and disadvantages. Choosing the appropriate guide rail type requires consideration of various factors such as motion accuracy, load capacity, cost, and maintenance based on the needs of the actual application. For example, high-precision and high-load applications may choose square rails, while cost-sensitive and lighter-load applications may use round or flexible rails.