Synchronous Belt Circular Guideway Conveyor Systems | High Precision Automated Circular Line Solutions

Synchronous Belt Circular Guideway Conveyor Systems | High Precision Automated Circular Line Solutions

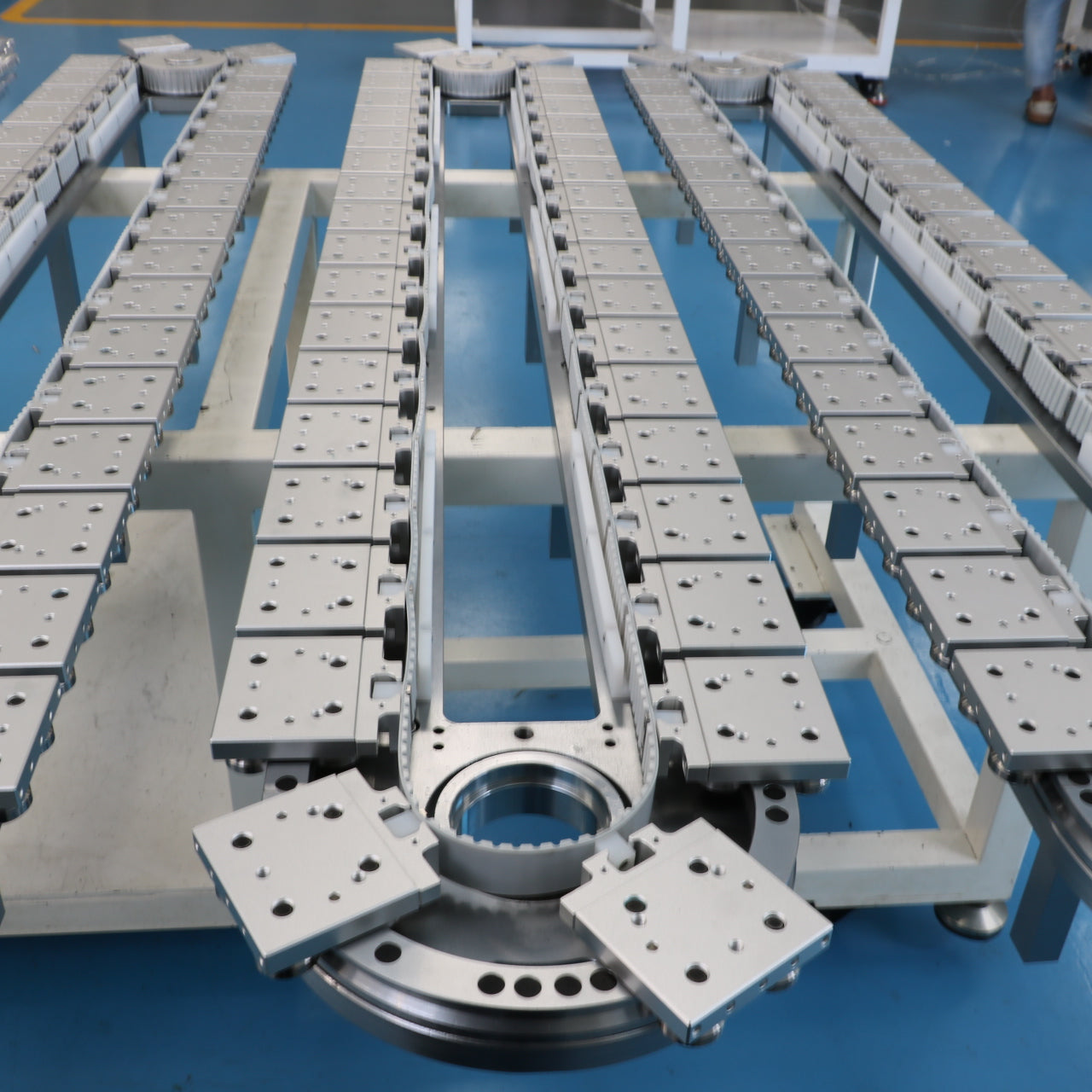

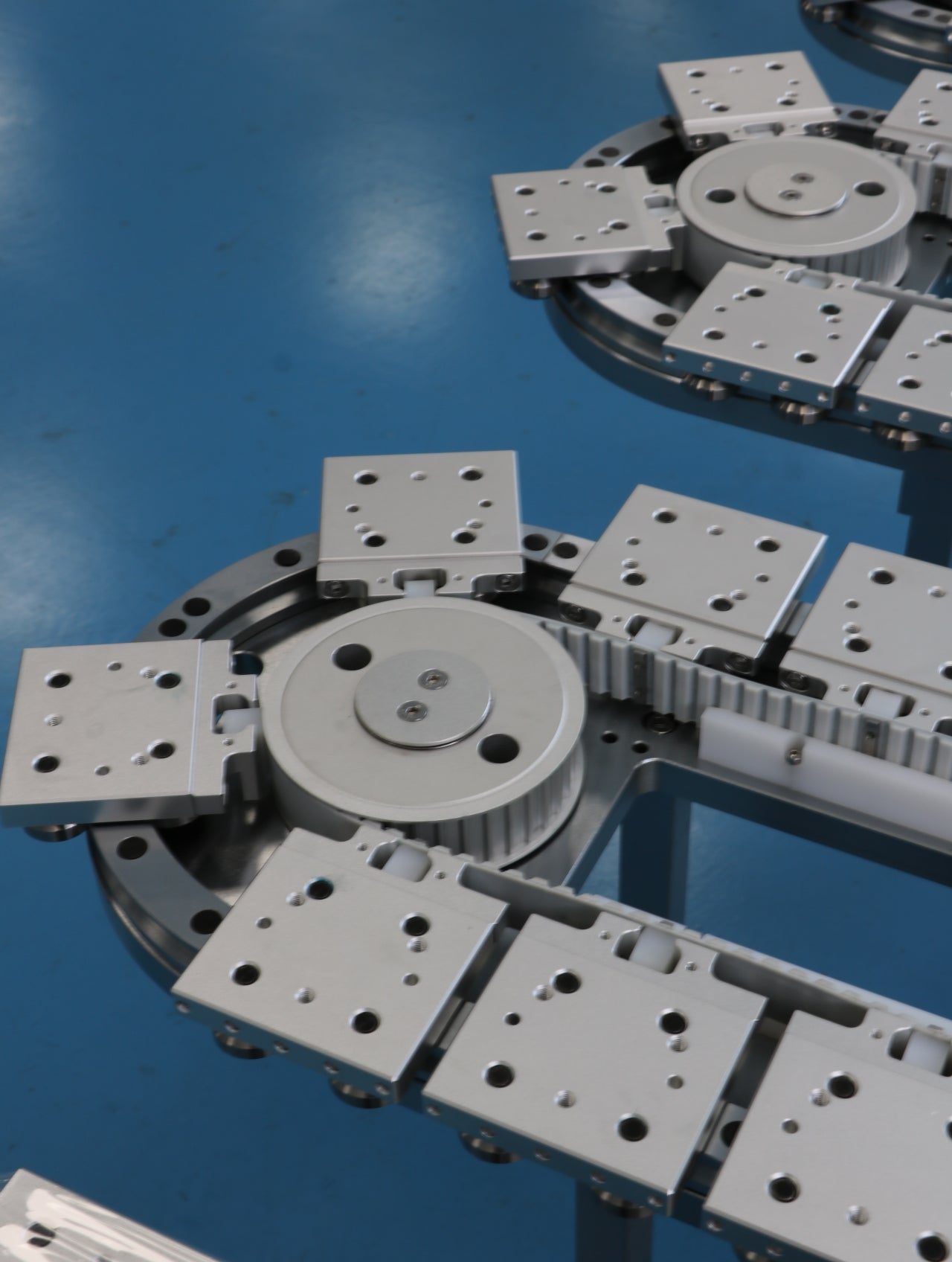

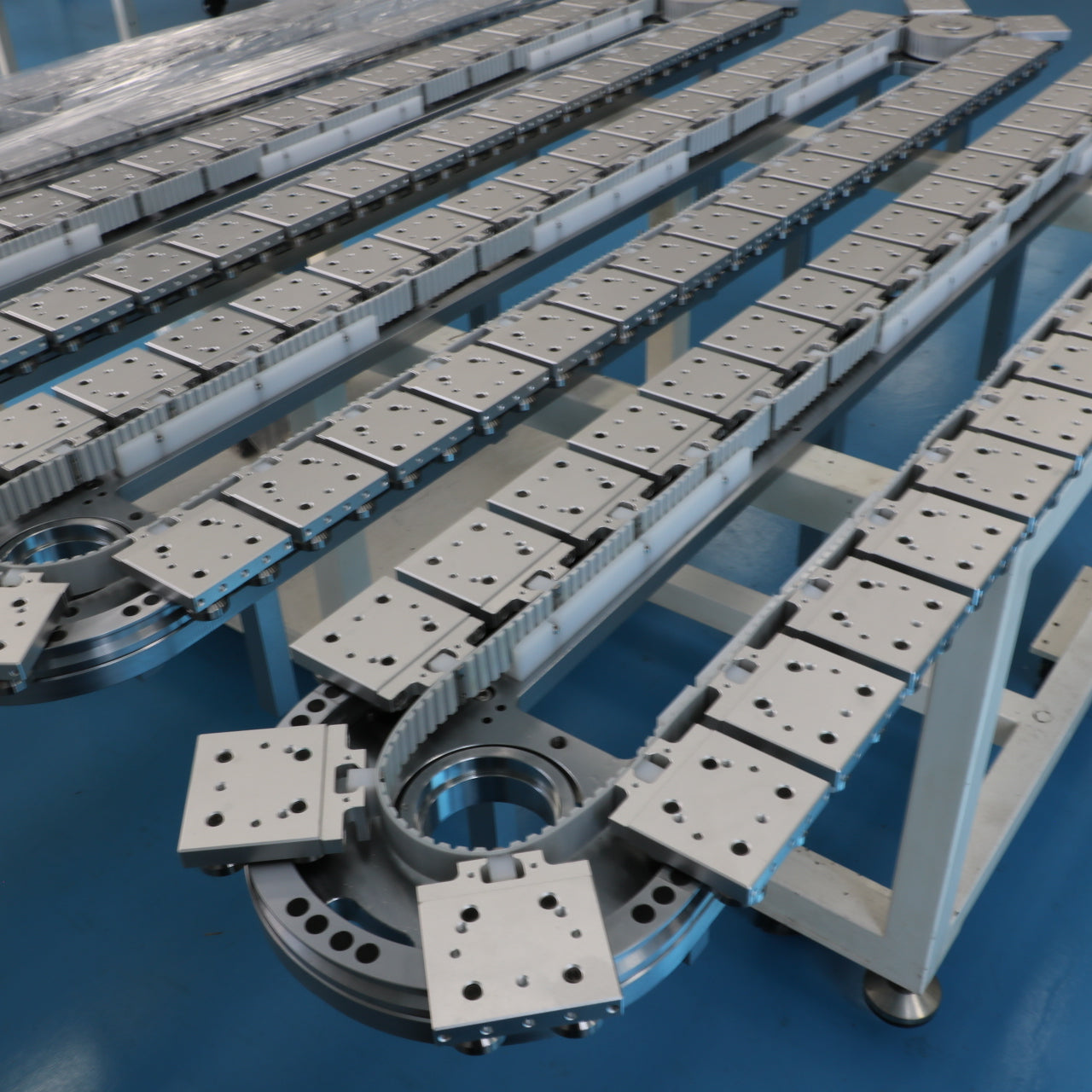

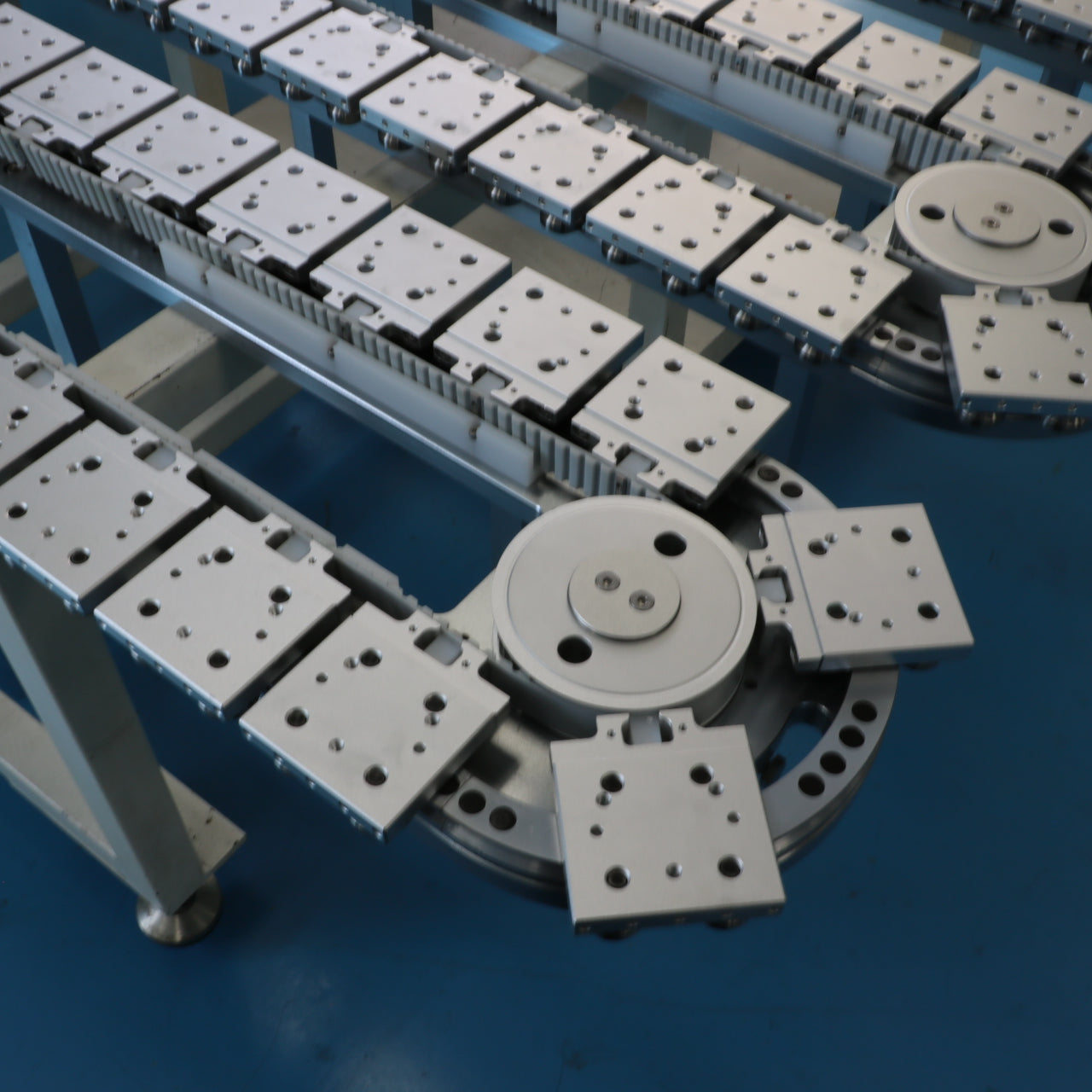

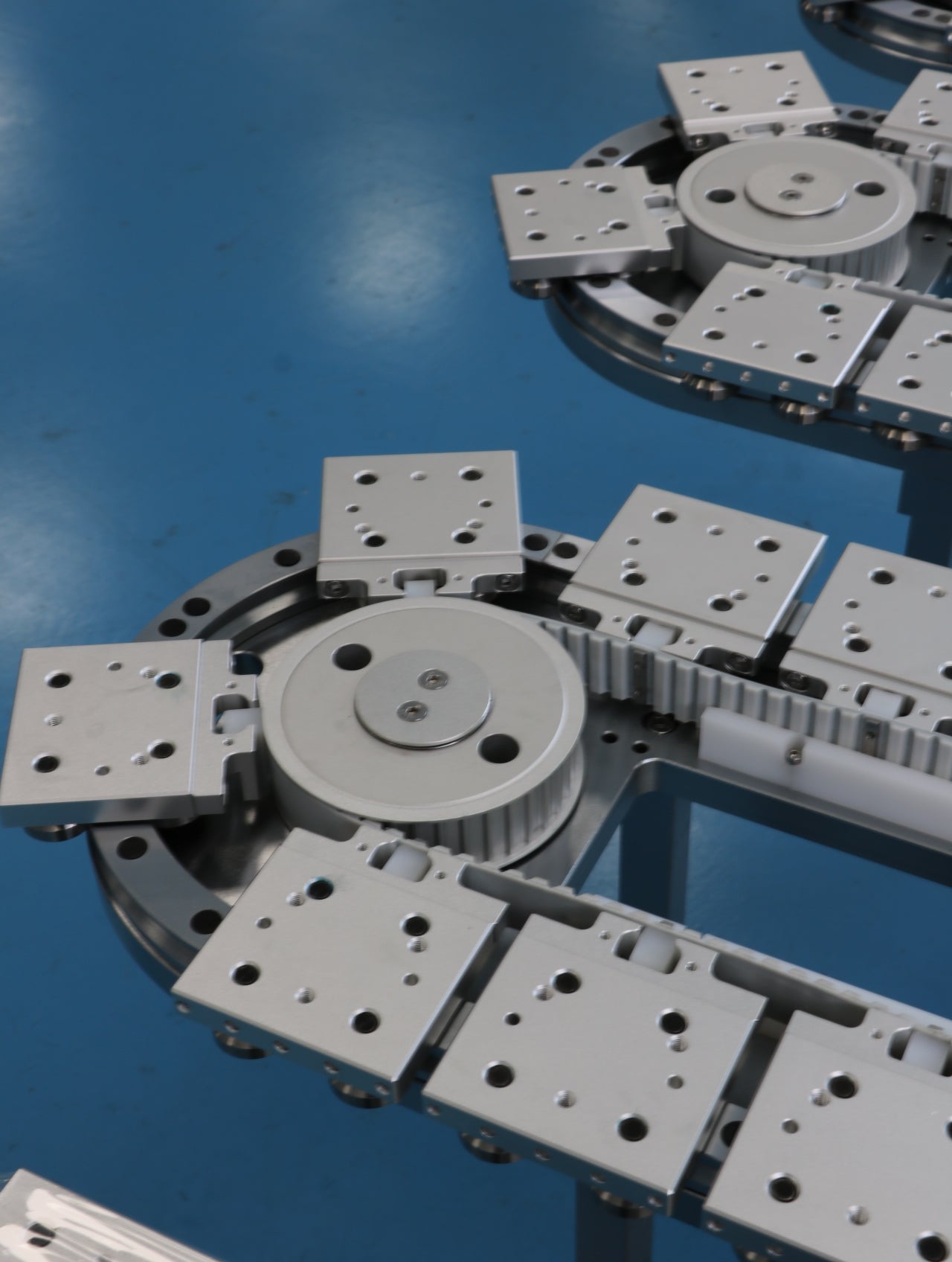

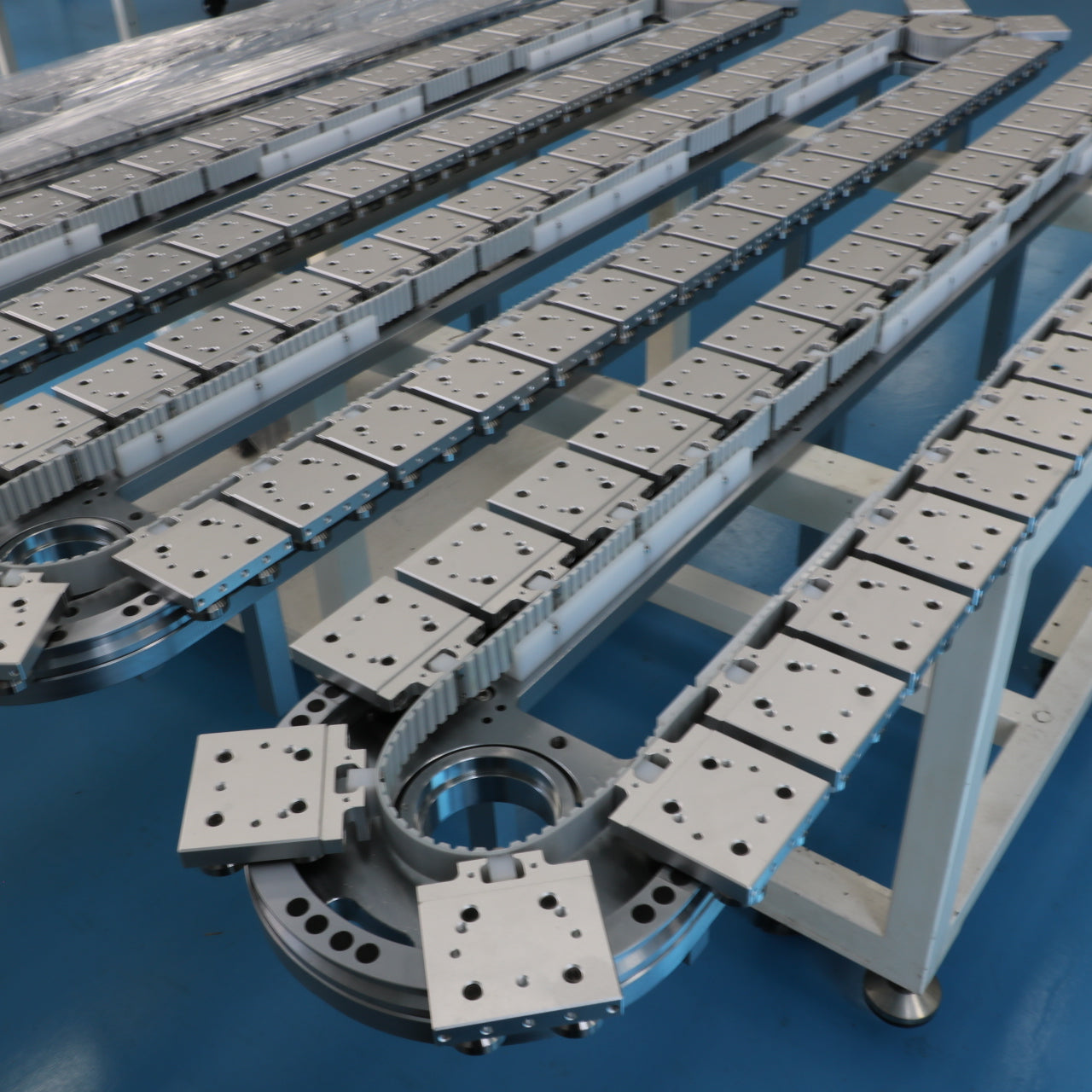

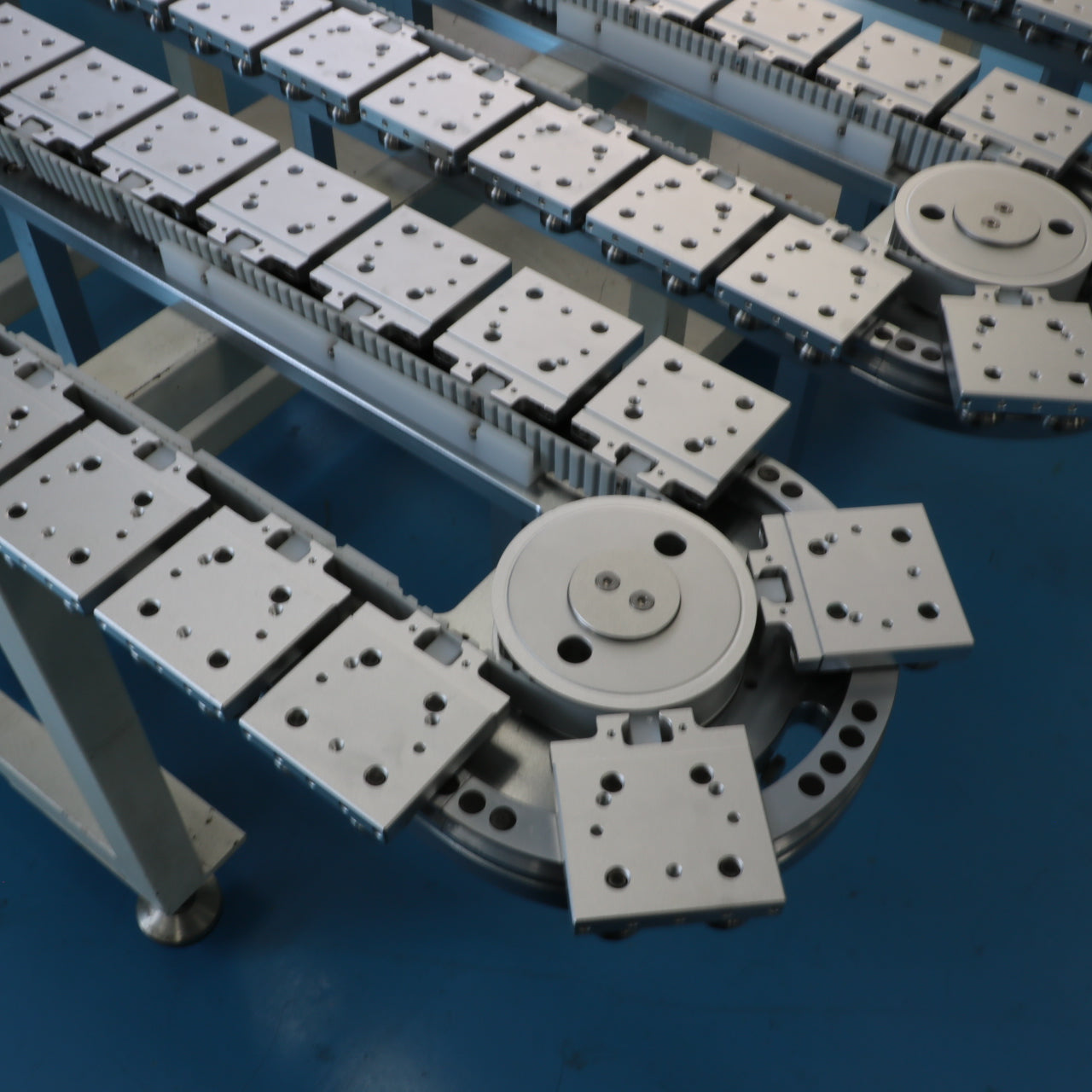

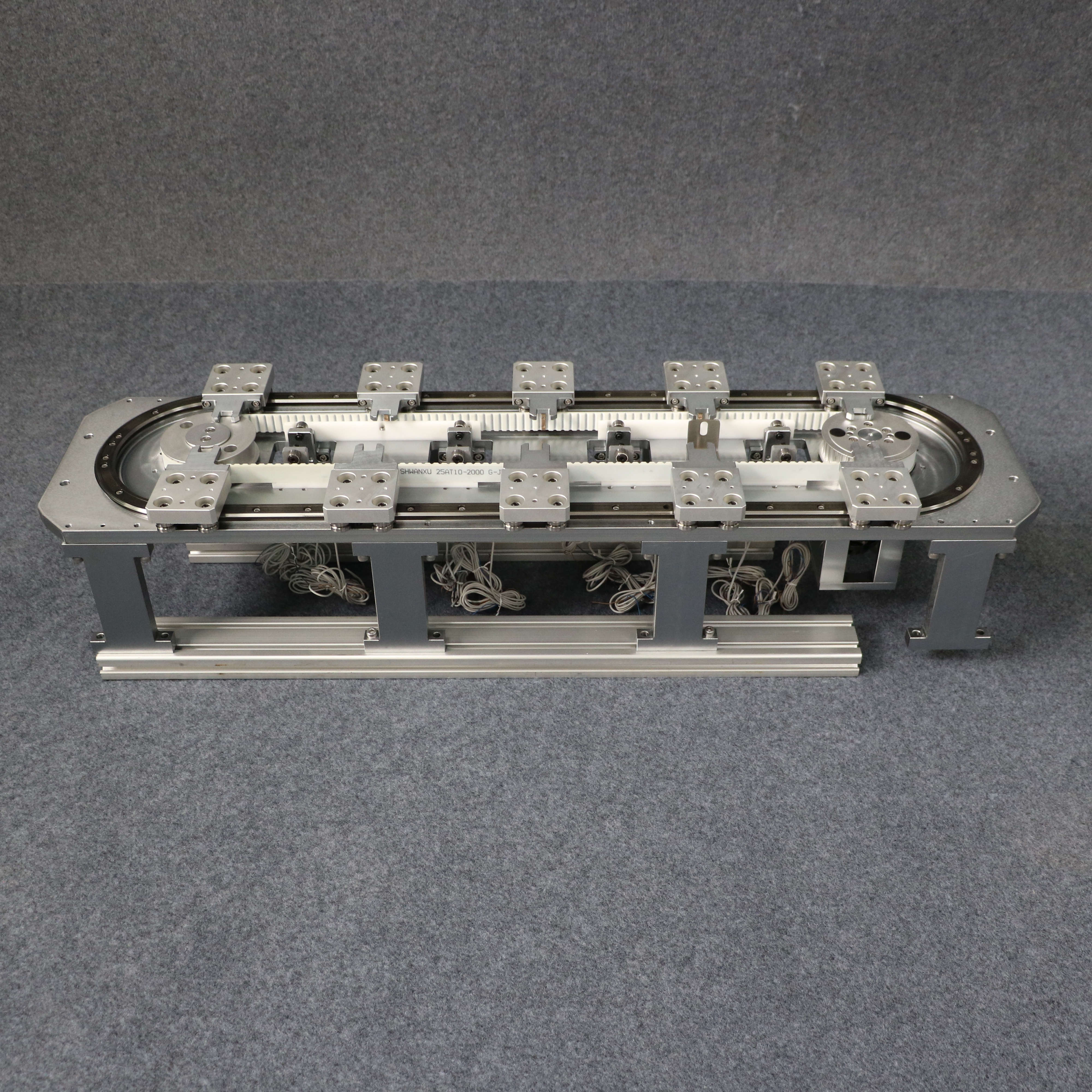

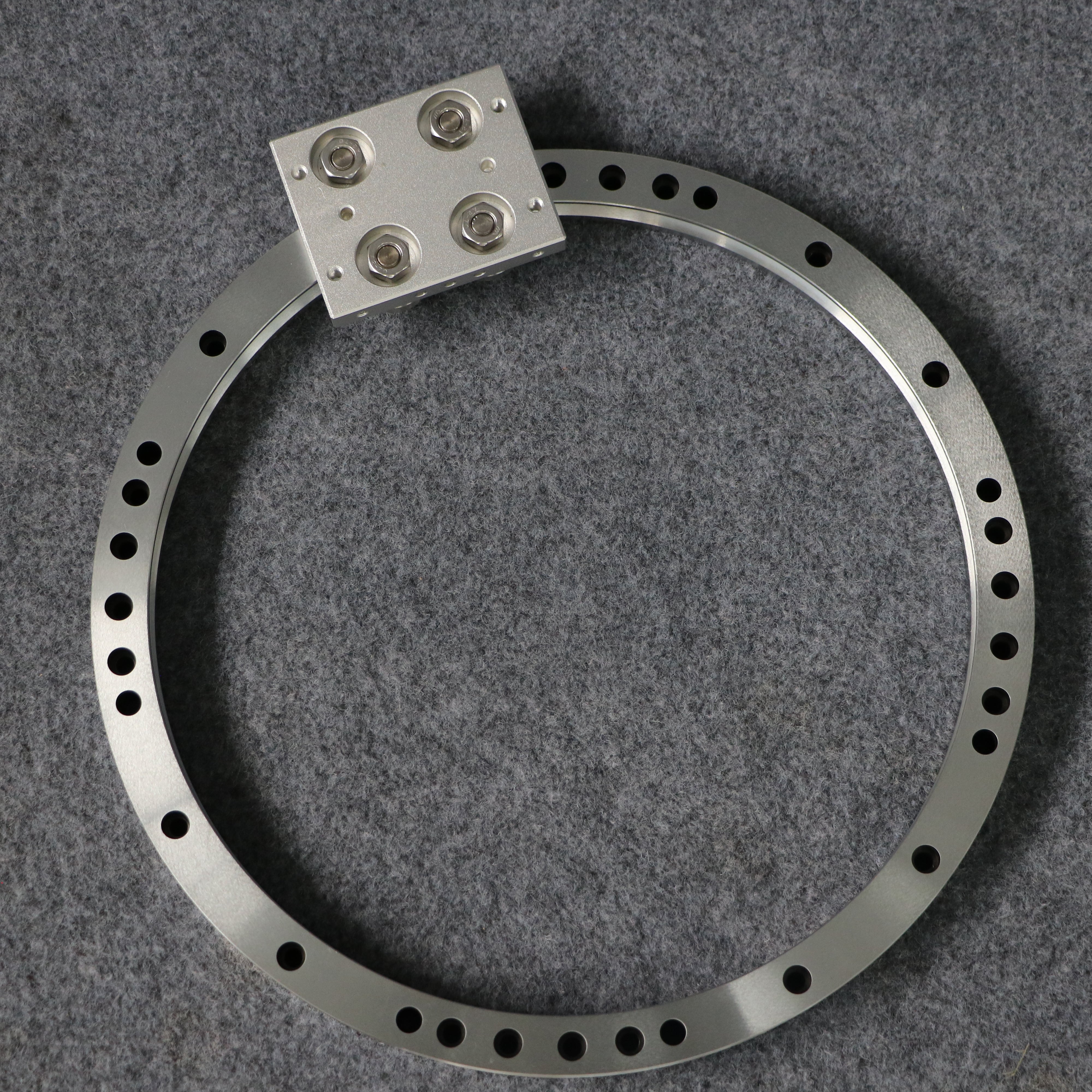

This synchronous belt circular guideway conveying system is a high-performance precision circular conveying assembly line designed for the demanding needs of modern intelligent manufacturing. The system consists of high-precision circular guide rail, linear guide rail, servo motor-driven slide and precision synchronous belt transmission mechanism as the core composition, realizing the smooth, high-speed, high-precision circular motion of the slide on the circular rail.

System core advantages

High precision and high rigidity: adopting the principle of V-type guide rail guiding, together with the secondary positioning mechanism (such as cylinder positioning), the system's repeatable positioning accuracy can reach up to ±0.05mm, or even ±0.01mm, which can meet the majority of the It can meet the most demanding requirements of automated assembly and testing processes.

High-speed and smooth operation: synchronous belt drive is quieter and cleaner than chain drive, and the highest running speed can reach 3m/s or even 5m/s, which significantly improves the production tempo.

Flexible customization: Oval, rectangular and other closed loop layouts can be customized according to customer needs. The length of linear section, the number and spacing of slides can be adjusted, easily realizing multi-station expansion.

Strong Load and Long-lasting Stability: The static load capacity of the slider can reach 1.6KN (about 163kg) or even higher (e.g. 3.6KN) depending on the specifications. The system is stable and has a long service life with low maintenance costs.

Easy integration: the system is usually mounted on an aluminum profile frame, which is easy to integrate into the equipment base and can easily work with other automation equipment such as manipulators and assembly mechanisms.

Typical Application Scenarios

This system is widely used in automation scenarios in various industries

Electronic assembly: cell phone parts assembly, hard disk automatic screw locking, PCB board conveying.

Packaging and Filling: Bottle filling and sealing, carton packaging in the food industry.

Testing and labeling: product performance testing, rotary testing, labeling, spraying.

Medical devices: rotation, sorting and assembly of precision medical devices.

New energy field: automatic production line feeding, conveying and assembling of lithium battery and new energy components.

Brief description of the working principle

When the system works, the servo motor drives the synchronous belt wheel and drives the high-strength synchronous belt to move. The slide is connected to the synchronous belt through the connecting parts (often including overload protection device), so that the synchronous belt is pulled by the synchronous belt in the circular track spliced by the linear guideway and circular guideway for circular motion. By setting up positioning devices (such as cylinder-driven positioning rods) at specific stations, precise stopping of the carriage can be realized, facilitating the execution of various operations.

We offer standard models and also support non-standard customization. If you have special needs, please contact us for exclusive solutions!

Share

A Chinese manufacturer specializing in the research and development of linear guide rails, arc guide rails (circular guide rails) and high-quality driven track systems (circular guide rail conveyor lines). Cooperating customers said: The driven track system is reasonably priced and of reliable quality, meeting needs and saving budgets. Give us a chance. Give you a future.